Safe, easy and cost effective hire.

Safe, Easy, and Inexpensive to Hire: Transform Your Site with Our Range of Crane Loading, Cantilever Loading, and Cantilever Building Platforms

A loading platform is generally designed to provide a stable and secure platform for loading and unloading goods and materials. There are several types, each with different advantages and limitations. Below, we explore three of the most important types: Crane Loading Platforms, Cantilever Loading Platforms, and Cantilever Building Platforms.

Crane Loading Platform

A crane loading platform refers to the type of platform designed for operations involving a crane. These platforms are typically made of steel or concrete and provide a high and stable base during crane operations. Equipped with safety features such as guardrails, anti-skid surfaces, and safety hooks, they ensure accidents are minimized during loading and unloading.

Cantilever Loading Platform

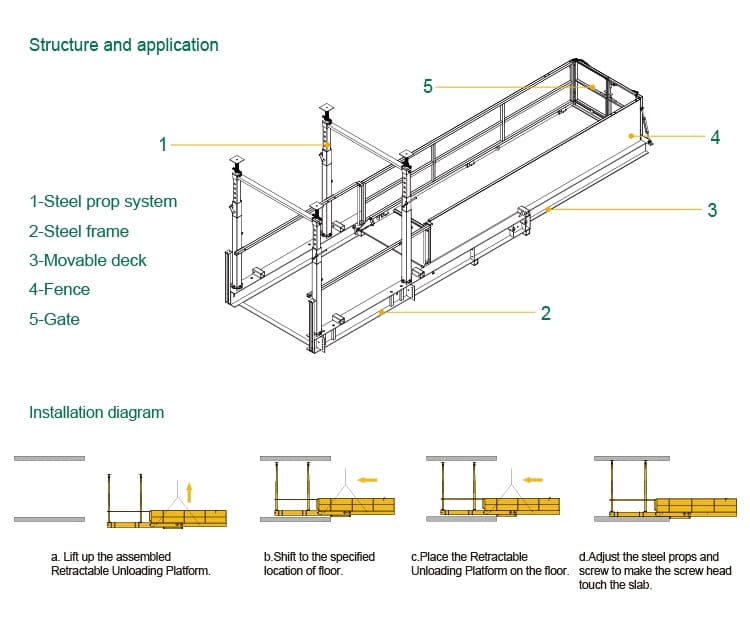

A cantilever loading platform is designed to attach directly to a building or structure. Made of steel, it is supported by a series of cantilevered beams extending from the building. Access is usually provided via stairs or ramps, ensuring a secure and stable platform for handling goods and materials.

Cantilever Building Platform

The cantilever building platform integrates seamlessly into a building or structure. Constructed from steel and supported by cantilever beams, it serves a variety of purposes, including storage, loading and unloading, and general maintenance activities. With access through stairs or ramps, it provides a safe working environment for personnel performing tasks at height.

Advantages and Disadvantages

- Crane Loading Platform: Offers mobility, versatility in handling diverse loads, and ensures a safe working environment for crane operators. However, it can be costly and requires a crane, which may not be practical for every purpose.

- Cantilever Loading Platform: Benefits include cost-effectiveness, adaptability for handling a wide range of loads, and the ability to attach directly to buildings or structures. The drawbacks are limited mobility and the need for a building or structure to attach it to.

- Cantilever Building Platform: Advantages include its ability to integrate into buildings or structures, versatility in handling various loads, and providing a safe working environment. Disadvantages include high costs and the necessity of an existing building or structure for integration.

Conclusion

Loading platforms are indispensable for businesses handling goods and materials. Choosing the right platform depends on a company’s specific needs, available space, and budget. Each type of platform offers unique advantages and limitations, and careful evaluation is essential to make the most suitable choice.