Safe, Easy, and Inexpensive to Hire: Transform Your Site with Our Range of Crane Loading, Cantilever Loading, and Cantilever Building Platforms

Two basic divisions for a loading platform may be their intended use and their supporting design. Platforms may be designed to gain different levels of height and accessibility, thereby serving diverse loading and unloading objectives. We here offer three categories of a more excellent surface on which cranes can operate safely-Crane Loading Platforms, Cantilever Loading Platforms, and Cantilever Building Platforms.

Crane Loading Platform

The crane loading platform is a platform constructed for direct crane operations. These platforms are usually constructed of either steel or concrete, providing a high and stable base during crane operations. Incorporated into the platform are safety features like guardrails, anti-skid surfaces, and safety hooks which help to minimize the potential for incidents while loading and unloading.

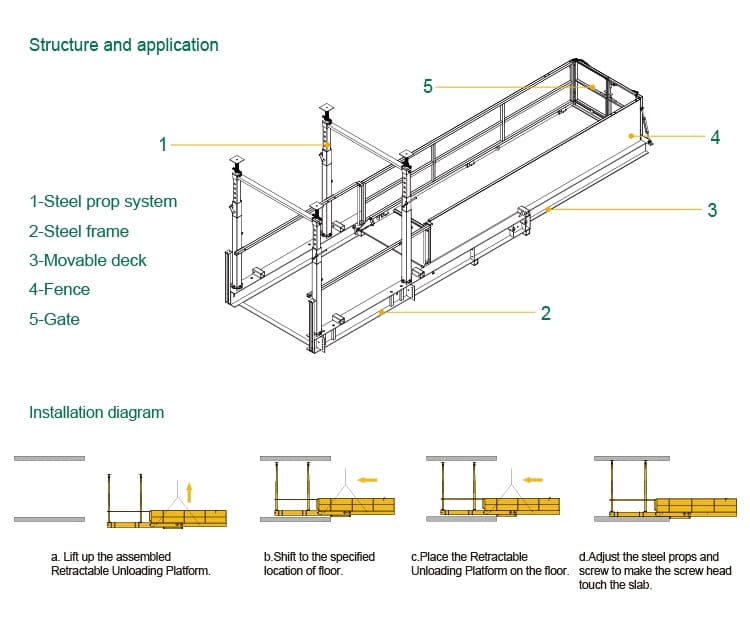

Cantilever Loading Platform

Cantilever loading platforms are bolted directly to the building or structure. They consist of steel and supported by cantilevered beams attached to the building. The access usually is by stairs or ramps, and they provide a steady working surface for goods and materials handling.

Cantilever Building Platform

It becomes an integral part of the building or structure it is associated with; made of steel with cantilever beams for support on either side of the building; used for storage, loading and unloading activities as well as general maintenance. Such platforms obtain access by stairways or ramps and provide a safe work area for personnel who work at height.

Advantages and Disadvantages

A crane loading platform provides great mobility and can handle different types of loads. Furthermore, it is safe for the crane operator. Disadvantages here are associated with a high cost, for it needs to be employed with a crane, which might not be feasible in all cases.

A cantilever loading platform is cheaper, versatile for working with many different types of loads, and easy to attach to buildings or structures. The disadvantages include reduced maneuverability, and it has to be tied to a building or structure for support.

The cantilevered building platform has the advantages of integration into buildings or structures, versatility in handling different types of loads, and ensuring a safe working area. Disadvantages could include higher costs and the need for an appropriate building or structure before such can be built.’

Conclusion

Loading platforms are indispensable in moving goods and materials. The choice of a suitable platform depends on the company’s individual needs, their space requirements, and commercial factors. Each platform has its unique advantages and limitations, hence assessment needs to be worked out suitably.